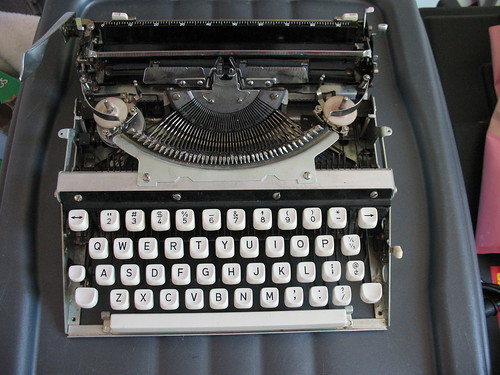

Step 1 is always get the shell off. I'm still considering the idea of a paint job, so I went ahead and pulled the platen off, too: my first-ever removal. Finding the little set screws was the challenge, and hopefully they'll tighten down more easily than they loosened. Also, the knobs had to be removed to remove the small metal panels on either side of the carriage.

A peep down the inside of the platen. The silver ends of the platen reflected light coming in from the outside. Is this a kaleidotyposcope?

And bloop into the bath goes the guts. This removed a good deal of gunk from the works, though I still needed to brush out the typefaces (which made more mess later.) Next time: brush out the typefaces first.

The shell is the next thing to get some careful attention while the innards dried in the sun. I peeled out the foam soundproofing from the bottom and sides, which reeked of old cigarettes, despite a day or two airing on my back porch. In a moment of questionable judgment, I spray-painted the grimy, yellowed knobs with some red dye leftover from the Pimpwriter.

Careful use of a knife and a hair dryer to soften the glue, and the badges came off with a small amount of coaxing. I'll flatten them again with a rolling pin before re-applying.

This was the part that took (and is taking) the longest. I used a wire brush on a drill to buff the paint off the outsides of the panels, after they had some ancient paint stripper brushed on. There's no going back now.

Only after I had spent too much time trying to steady these pieces against a spinning drill (and often missing) did it dawn on me that I have a palm sander in the garage. That made much shorter work of the big, flat areas, but I still need to do some obvious touch-ups. All the main surfaces are done, though. Now I have to clean it up, and maybe try a finer grit on the palm sander to polish the metal. I haven't decided yet.

I do know that I don't have the patience to do all the interior surfaces. Chances are I'll just dress those up with some new felt or sticky-back foam from the craft store. Stay tuned!

7 comments:

I've been considering using Plasti-Dip spray on the interior surfaces of a machine, to see if that helps as a sound-deadener. Not sure whether that would work.

I have to find something to do with the Plasti-Dip, which proved unsuitable for platen re-surfacing. It stuck fine, and - though it wasn't the smoothest surface - probably would have worked if the stuff didn't get nicked off so easily when you're re-installing the platen. So, I had to yank the stuff off. Odd that it was so doggone hard to get it off when I actually wanted it off. Imagine some kind of horrific prophylactic snafu, and you know what that process looked like.

Waiting with anticipation for the next installment.

GREAT WORK so far!

I agree with Cameron! This is fun! Can't wait till the next episode. :-D

Nice work. I found some thick felt with adhesive backing on Ebay. Before that I was using thick felt sprayed with 3M adhesive. I have also been able to get smoke stink out of felt with a mist of water and baking soda or Fabreze. My TP1 reeked of smoke stink. A few days in the sun and then baking soda and Fabreze to the case and now it's fine.

Has anyone considered automotive sound deadening undercoat on the inside of a typewriter?

I look forward to your next post.

Ohhhhh... eager to see the outcome of this!

You should get a huge kick out of persevering through finer grits of wet and dry, to wire wool and finally a polishing compound. I mean, you might as well now you got so far...

And I love the absurdity of expending a Great Deal of Effort on a K-Mart typewriter.

If you get the finish good enough, you could even gold plate it!

Really cool. I am very curious to see the outcome. I love Typewriter Science Experiments.

Best,

Joe Ahearn

http://batterrier.com

Post a Comment